Sewing Technology

Sewing Machine

A sewing machine is a textile machine used to stitch fabric, paper, card and other material together with thread. It is an important part of the garment manufacturing industry as well.

Innovation History of Sewing Machine

The Invention of the Sewing machine was the combined ideas and work of many inventors. In 1790, Thomas Saint, an Englishman, took out a patent on a machine for “quilting, stitching, and sewing, and for making shoes, and other articles. Saint’s machine can made only chain stitch.

In 1832, Walter Hunt developed a machine in his shop in New York City. He incorporated two new ideas i.e. eye-pointed needle and a locking stitch. Many other people contributed to the development of the sewing machine. In 1845, Elias Howe, an apprentice watchmaker from Boston, made a sewing machine that had a curved eye-pointed needle and an under-thread shuttle. This machine could sew 250 stitches per minute. That was five times as fast as the fastest hand sewer. In 1846, Isacc M. Singer, an American, produced a machine that had a straight needle and could sew continuously.

Different Parts of a Sewing Machine and Their Function

They are different types of sewing machines that are available in the market. The basic functionality of the machine is one and the same.

- Bed:The role of this part is to stabilize the machine to rest in a permanent place.

- Bobbin: It holds the bobbin thread

- Bobbin Case: It holds the bobbin in the machine and regulates the tension of the bobbin thread.

- Bobbin Cover: It covers the bobbin and bobbin case in the machine.

- Bobbin Winder Spindle: It winds the thread from the spool to the bobbin, mechanically.

- Throat/Needle Plate: It is a semi-circular disc with a hole to allow the needle to pass through it.

- Needle: This is the essential and most sensitive instrument of the machine which holds the thread and sews the fabric.

- Feed Dogs: The feed dogs feed the fabric in the sewing direction.

- Presser Foot: The presser foot applies pressure consistently on the fabric as the sewing takes place. Attach the appropriate presser foot for the selected stitching.

- Pressure Foot Lever: The primary function of this part is to raise or lower the foot level.

- Thread Guides: This is a small hole that guides the thread from the spool to the needle.

- Thread take-up lever: The take-up lever pulls the thread back after each stitch, so that the stitches will lay evenly into the fabric.

- Thread Tension Control: This determines the tightness or looseness of the stitch.

- Spool Pin: The Spool pin holds the spool of thread. It can be horizontal or vertical in place.

- Hand Wheel: It is used to manually raise and lower the needle.

- Pattern/Stitch selector: It determines the stitch type such as straight stitches or an embroidery stitch or zig-zag.

- Stitch width regulator: It determines the length of the stitches on the fabric. The range on this machine is from 0 to 4 (0=the shortest stitch, 4=the longest).

- Stitch width regulator: It allows the user to control the width of the stitches on the fabric. The range on this machine is from 0 to 4 (0=the shortest stitch, 4=the longest).

- Food Pedal: Foot Pedal regulates the starting, running, and stopping of the machine

- Stitch width regulator: It allows the user to control the width of the stitches on the fabric. The range on this machine is from 0 to 4 (0=the shortest stitch, 4=the longest).

- Reverse Lever: The liver works to depress the lever which enables the mechanism to move backward or in reverse.

- Stitch length regulator: It determines the length of the stitches on the fabric. The range on this machine is from 0 to 4 (0=the shortest stitch, 4=the longest).

How a Sewing Machine Work?

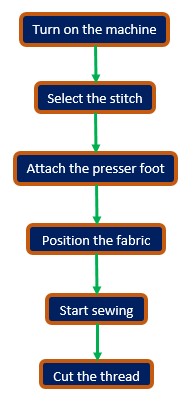

General Sewing Procedure

Follow the basic procedures below to sew.

(0)

Different Parts of a Sewing Machine and Their Function

0 comments:

Post a Comment