Saturday, August 26, 2017

Modular Production System | Toyota Sewing System | Cellular Garment Manufacturing System

Modular Production System | Toyota Sewing System | Cellular Garment Manufacturing System

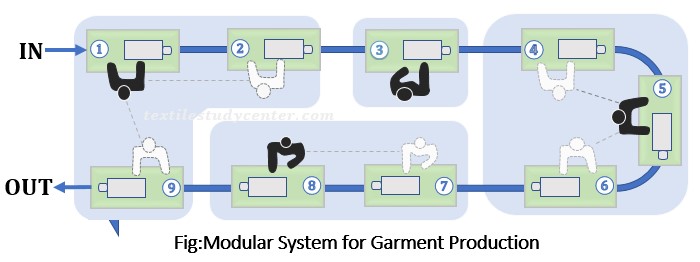

Modular production system involves a group of four to seventeen people who set their own standards and work together to produce a finished garment. They work as a team or module and each team member works on more than one operation. In this system, operators help each other to finish the garment quickly and the team is fully responsible for production and quality. The number of teams in a plant varies with the need of the industry, size of the industry and product line in garments. This system MPS is the perfect solution for the apparel manufacturer where quick response is needed. This system is also popular as a Cellular Garment Manufacturing, flexible work groups or Toyota Sewing System (TSS).

Features of a Modular Production System

Usually U-shaped layout with more workplaces than operators.

Each operator performs approximately 2-4 operations, depending on the product.

The work flow is sequential.

WIP is less and productivity is high in this production system

The operators stand /sit at their stations and rotate in different sewing machines to complete the operations.

Pull-type production systems, in which the job order arrives from the last step to previous steps

Time spent per garment is also little; e.g. T-shirt 3 mins, Pull-on pants 6 mins., unstructured jacket 25 mins., lined blazer 40 mins., tailored coat 120 mins.

Advantage

MPS leads to cost savings.

The system is highly flexible with style changes and permits better line balancing.

Enables fast throughput time, lower WIP, and small batch size can be achieved.

Peer pressure encourages a team spirit and discourages absenteeism.

Productivity of human labour

Reducing supplies of unfinished production

Required less floor space

Improved quality of product

Disadvantages

High capital investment is needed in initial training workers to deal with several tasks at one station.

This system requires a higher degree of communication and cooperation among operators, mechanics, and supervisors.

Operators cannot develop the rhythm and pace of high performance.

No harmony between team members can cause problems, thus loss in production.

Depend on the Team for whole Production.

Applications:

Fashioned garments with quick response.

Orders with low volume and frequent changes.

Company with mutual trust between management and operators.

(2)

Modular Production System | Toyota Sewing System | Cellular Garment Manufacturing System

Friday, August 25, 2017

Acid wash | Random wash | Acid Wash by Stones

Acid wash / Random wash

At present times, the most popular denim garments are random washed among the fashionable people. When solid washed the fading, effects are even and uniform in the garments but when random washed effects are uneven.

The first step of acid wash is rinse if needed then desized by enzyme (alpha amylase ) or by desizing chemicals according to the fabric of the garment. Then wash by cellulosic enzymes if needed to bring abrasion effects. After that random wash procedures starts by making potassium per manganate (KMnO4)or bleach ( NaOCl ) solution with required amount of water or phosphorous acid and uneven effect making elements like stones, balls, towels and thermopols. To bring random effects on garments must be wet so the garments should be hydro extracted before throwing to the belly machine.

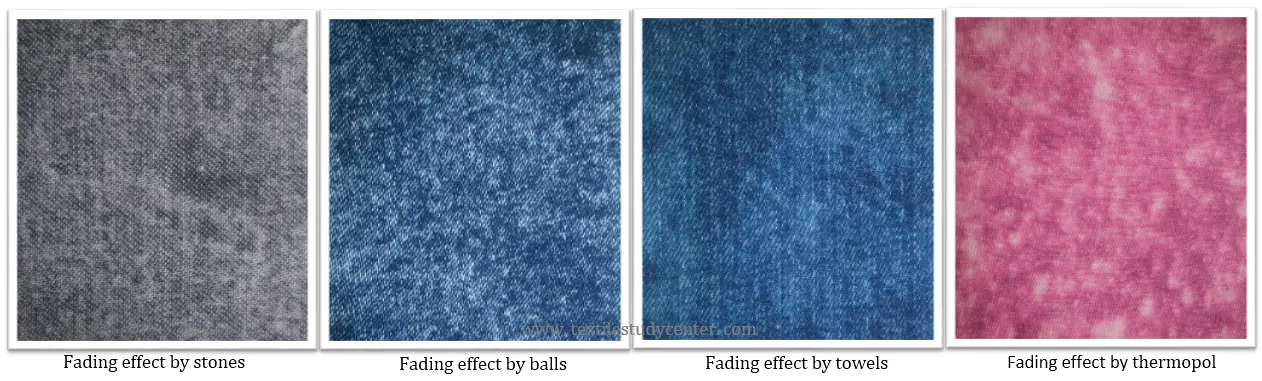

Various types of effects can be produced by following elements are given below:

- Pumice Stones: Makes small fading effects like drop of pin point on the surface of the garments.

- Balls: circular and small line fading effects

- Towels: big uneven fading effect like sweeping randomly

- Thermopols: Random sized fading effect sometimes looks like lengthwise fading

Acid Wash by Stones :

At first pumice stones must be soaked by solution of strong oxidizing agents like sodium hypochlorite ( 5-10% ) (NaOCl) or potassium permanganate (KMnO4) (3-6% ). Excess liquor is removed from the stones. Certain amount of treated stones and garments is dry tumbled in the belly washing machine to bring the desired random effects on the garments is called acid washing or snow washing or ice washing,

Stones can be treated by two ways like –

1. Stones are taken into a net or mesh fabric and soaked into the solution then dried on air.

2. An excess piece of fabric is placed into the belly machine, then stones are gathered on the fabric and the solution is sprayed on those stones and run the machine for 2-3 mins by tumbling to remove excess solution and also to mix them properly.

The soaked stones and wetted garments are loaded into the belly machine. According to the desired fading effect, the machine is tumbled 2-10 mins. The degree of color fading depends on the stone ratio, concentration of the chemicals, types of garments and dyestuff’s. After getting the desired effect, the garments are loaded on another machine for rinse for 3-4 mins. As KMnO4 or NaOCl are hazardous chemical so neutralization is mandatory for further processing. If KMnO4 is used then MnO2 is formed which leads to brown / orange tone and must be removed by oxalic acid and if NaOCl is used then a reducing agent like sodium bisulphite is used for neutralization. Finally the garment treated with softener, hydro extracted and dried by dryer.

Acid wash | Random wash | Acid Wash by Stones

Acid wash | Random wash | Acid Wash by Stones

Systems of Yarn Count Measurement

Systems of Yarn Count Measurement

What is count/yarn count ?

Count or yarn count is a numerical expression which indicates the coarseness or fineness of a yarn. In other words, yarn count is a number indicating the mass per unit lengh or the length per unit mass of the yarn.

There are mainly two systems or ways of yarn count measurement, these are :

(a) Indirect System / Fixed weight system

( length per unit mass )

(b) Direct system / Fixed length system

( mass per unit length )

Indirect system of yarn count measurement

The indirect system or fixed weight system is the yarn count system where the count of a yarn is calculated by measuring the length of a fixed / definite mass.

In this system, the count of yarn is the number of length units in one weight unit. So, the count number indicates the length per unit mass of the yarn. That is why, higher the count, finer the yarn. In indirect count system, the mass of yarn is fixed and the length of yarn varies according to its fineness.

This system is widely used for measuring count of cotton yarns.

The following formula is used to calculate yarn count in indirect system :

N = (L × w) / ( l × W)

Where, N = yarn count

L = the length of the sample

w = ” unit of weight ” of the system

W = the weight of the sample

l = ” unit of length ” of the system

Some of the most commonly used indirect systems include : English cotton count (Ne) system, Metric count (Nm) system, Worsted count (NeK) system & Woollen count system. These systems are described below :

English cotton count (Ne) :

In this system, yarn count is defined as the number of hanks of 840 yards per pound.

For example, yarn count 30 Ne means that there are 30 hanks (each hank consisting of 840 yards of yarn) per 1 lb or 1 pound of that yarn (length per mass) . In other words, if a yarn has a count of 30 Ne , it means that 30 hanks (of 840 yards) of that yarn will weigh 1 pound.

Note :

- If (30×840) or, 25200 yards of a yarn weigh 1 pound then the yarn count will be 30 Ne

- Ne count is also expressed with ’s . (e.g. 50’s cotton yarn)

Metric Cotton Count (Nm) :

In Metric cotton count system, yarn count is defined as the number of hanks of 1000 m per 1 kilogram of that yarn.

For example, yarn count 30 Nm means that there are 30 hanks of 1000 m per 1 kilogram (kg) of that yarn. In other words, yarn count 30 Nm means 30 hanks (each hank consisting of 1000m) of that yarn will weigh 1 kg.

Worsted Count (NeK) :

It is defined as the number of hanks of 560 yards per 1 pound of that yarn.

For example, yarn count 30 NeK means that there are 30 hanks of 560 yards per one pound (1 lb) of that yarn. In other words, yarn count 30 NeK means 30 hanks (each hank consisting of 560 yards) of that yarn will weigh 1lb.

Woollen Count :

In this system, yarn count is defined as the number of hanks of 256 yards per pound.

For example, woollen yarn count 30 means that there are 30 hanks (of 256 yards) per 1 lb or 1 pound of that yarn. In other words, yarn count 30 Ne means 30 hanks (each hank consisting of 256 yards) of that yarn will weigh 1 pound.

These indirect yarn count systems can be expressed briefly in the chart below :

Indirect yarn count system

[table id=14 /]

Direct system of yarn count measurement

The direct system or fixed length system is the yarn count system where the count of a yarn is calculated by measuring the mass of a fixed / definite length.

In this system, the count of yarn is the number of weight units per length unit. Here, the count number indicates the mass per unit length. So, higher the count, coarser the yarn. In direct count system, the length of yarn is fixed and the mass of yarn varies according to its fineness.

This system is commonly used for polyester, nylon, silk, acrylic & jute yarn.

The following formula is used to calculate yarn count in direct system :

N = ( l × W) / L

Where, N = yarn count

L = the length of the sample

W = the weight of the sample

l = ” unit of length ” of the system

Some of the most commonly used direct systems include :

Tex, Denier, Pounds per Spyndle, DeciTex (dtex) MilliTex (mtex) KilloTex (ktex)

Tex :

The yarn number or count in Tex system is the weight in grams of 1000 m of yarn.

For example, yarn count 30 Tex means that there are 30 grams of yarn per 1000 m or 1 km of that yarn (mass per length) . In other words, yarn count 30 Tex means 1000 m of that yarn will weigh 30 gm.

Denier :

The yarn number or count in Denier system is the weight in grams of 9000 m of yarn.

For example, yarn count 30 Denier means that there are 30 grams of yarn per 9000 m or 9 km of that yarn. In other words, yarn count 30 Denier means that 9000 m of that yarn will weigh 30 gm.

Pound per Spyndle / Jute count :

The yarn number or count in Pound per Spyndle system is the weight in pounds of 14,400 yards of yarn.

For example, yarn count 20 Pound per Spyndle means that there are 20 lbs of yarn per 14400 m yards of that yarn. In other words, yarn count 20 Pounds per Spyndle means that 14400 m of that yarn will weigh 20 lbs.

deciTex (dTex) :

The yarn number or count in deciTex system is the weight in grams of 10,000 m of yarn.

For example, yarn count 30 deciTex means that there are 30 grams of yarn per 10,000 m or 10 km of that yarn (mass per length). In other words, yarn count 30 dTex means 10,000 m of that yarn will weigh 30 gm.

miliTex (mTex) :

The yarn number or count in miliTex system is the weight in milligrams of 1000 m of yarn.

For example, yarn count 30 miliTex means that there are 30 milligrams of yarn per 1000 m or 1 km of that yarn. In other words, yarn count 30 mTex means that 1000 m of that yarn will weigh 30 milligrams.

kiloTex (kTex) :

The yarn number or count in kiloTex system is the weight in kilograms of 1000 m of yarn.

For example, yarn count 30 kiloTex means that there are 30 kilograms of yarn per 1000 m or 1 km of that yarn. In other words, yarn count 30 kTex means 1000 m of that yarn will weigh 30 kilograms.

These direct yarn count systems can be expressed briefly in the chart below :

Direct yarn count system

[table id=15 /]

Systems of Yarn Count Measurement

Systems of Yarn Count Measurement

Textile Printing | Feature of Textile Printing | Process flowchart of textile printing

Textile Printing

The word of “printing” has derived from a Latin word which means “pressing “. It implies a process that uses pressure. Textile printing is one kind of localized dyeing where dyes or pigments & chemical applied by any method which can produce a particular effect of color on fabric according to design. In a word, Applying colored patterns and designs to decorate a finished fabric is called ‘Printing’. In a proper printed fabric, the color is affixed to the fiber or fibre surface (pigment) so that it may not be affected by washing and friction or any other means. It’s a combination of art, engineering & dyeing.

Feature of Printing:

Printing is applied in form of design or pattern. Single or multi color can be applied.

A special type of viscous liquid is used to hold the dye/pigment & chemical which is called ‘Print paste’.

High viscosity of print paste helps dye to adhere to surface of fibre. But the fixation is done by applying steam which is called ‘curing’

For dyeing low viscous or aqueous medium is used but printing is done in wet viscous medium.

The Dyes used for printing mostly include vat, reactive, naphthol (azoic) and disperse dyes which have good fastness properties.

The pigments, which are not truly dyes, are also used extensively for printing. About 96% is done by pigment. These colors are fixed to the fiber through binder.

Alternative process of textile printing :

There are some alternative processes for applying colorful design on fabric. But printing is the cheapest process that’s why it is widely used. The other processes are……..

By dyed yarn in form of woven fabric.

Embroidery

Knitted with colored yarn.

Appliqué etc.

Difference between Dyeing and Printing :

[table id=16 /]

Process flowchart of textile printing:

Fabric preparation

Preparation of printing device (block/flat or rotary screen, roller)

Printing paste preparation

Impress on fabric

Drying the printed fabric

Fixation by curing

Washing & soaping

Finally dry

Delivery

Different styles / techniques of printing:

Direct style

Resist style

Discharge style

Special style

Some special printing style…..

Flock style

Dyed style

burnt out style

blotch printing

air brush ( spray) printing

photo printing

batik / tie dye etc.

Textile Printing | Feature of Textile Printing | Process flowchart of textile printing

TEXTILE BOOKS FREE DONWLOAD

YES YOU CAN DOWNLOAD THE BOOK YOU WANTED

YES YOU CAN DOWNLOAD THE BOOK YOU WANTED

We will give you any of the 2 books from the below list if you fulfill our conditions.

If you want to download this book , you need to write an unique article about textile related topics.

The article must be at least 500 words or above and contains valuable information.

No copy paste is allowed and we will check plagiarism to confirm.

You can send your article to our emails :

Zahirul Islam ( zahir007247@gmail.com )

Sohanur Rahman Sobuj ( sobujbutex93@gmail.com )

Books on Fibre / Yarn / Spinning / Testing

- A Practical Guide to Fibre Science Preview

- A Practical Guide to Quality Management in Spinning Preview

- A Practical Guide to Textile Testing Preview

- A Technical Handbook on Bituminized Jute Paving Fabric Preview

- Advanced Fiber Spinning Technology Preview

- Advances in Filament Yarn Spinning of Textiles and Polymers Preview

- Advances in Silk Science and Technology Preview

- Advances in Wool Technology Preview

- Advances in Yarn Spinning Technology Preview

- Bast and Other Plant Fibres Preview

- Biodegradable and Sustainable Fibres Preview

- Cotton Fiber Chemistry and Technology Preview

- Cotton Science and Technology Preview

- Engineering techniques of ring spinning Preview

- False twist textured yarns_ Principles, process and applications Preview

- Fancy Yarns Their Manufacture and Application Preview

- Fatigue Failure of Textile Fibres Preview

- Fibre Structure Preview

- Friction in Textile Materials Preview

- Fundamentals of Fiber Science Preview

- Fundamentals of yarn winding Preview

- Handbook of fibre rope technology Preview

- Handbook of natural fibres_ Types, properties and factors affecting breeding and cultivation (vol:1) Preview

- Handbook of natural fibres_ Processing and applications (Volume 2) Preview

- Handbook of Textile Fibre Structure (Volume 1) Preview

- Handbook of Textile Fibre Structure (Volume 2) Preview

- Handbook of Textile Fibres. Volume 1 Natural Fibres Preview

- Handbook of Textile Fibres. Volume 2 Man-Made Fibres Preview

- Handbook of Textile Testing and Quality Control Preview

- Handbook on cotton spinning industry Preview

- Handbook of Worsted Wool and Blended Preview

- Handbook of Yarn Production Technology, science and economics Preview

- Identification of Textile Fibers Preview

- Mechanics of fiber and textile reinforced cement composites Preview

- Modern Approach to Maintenance in Spinning Preview

- Physical Properties of Textile Fibres Preview

- Physical Testing of Textiles Preview

- Polyesters and polyamides Preview

- Polyolefin Fibres Industrial and Medical Applications Preview

- Process control and yarn quality in spinning Preview

- Process Management in Spinning Preview

- Reference Book of Textile Technology_Man Made Fibers Preview

- Reference Book of Textile Technology_Spinning Preview

- Regenerated_Cellulose_Fibres Preview

- Role of yarn tension in weaving Preview

- Smart composite coating and membranes Preview

- Silk, Mohair, Cashmere and Other luxury fibres Preview

- Silk, Processing, Properties and Applications Preview

- Specialist Yarn and Fabric Structures-Developments and Applications Preview

- Synthetic fibres_ Nylon, polyester, acrylic, polyolefin Preview

- Technical Textiles Yarns Industrial and medical applications Preview

- Textile mechanisms in spinning and weaving machines Preview

- Textile Spinning, Weaving and Desizing Preview

- The chemistry of textile fibres Preview

- Wool Science and Technology Preview

- Woollen and Worsted Woven Fabric Design Preview

- Yarn Technology Preview

- Yarn Texturing Technology Preview

Books on Fabric / Knitting / Weaving / Non-woven

- Advances in Knitting Technology Preview

- Advances in Technical Nonwovens Preview

- Advances in Woven Fabrics Technologies Preview

- Analysis of Woven Fabrics Preview

- Applications of Nonwovens in Technical textile Preview

- Braided structures and composites_production, properties, mechanics, and technical applications Preview

- Braiding technology for textiles Preview

- Circular Knitting Preview

- Composite nonwoven materials_ Structure, properties and applications Preview

- Composites Forming Technologies Preview

- Effect of mechanical and physical properties on fabric hand Preview

- Fabric dyer’s dictionary Preview

- Fabric Structure and Design Preview

- Fabric Testing Preview

- Fabric Structures in Architecture Preview

- Fundamentals and Advances in Knitting Technology Preview

- Geosystems_ Design Rules and Applications Preview

- Handbook of Advances in Braided Composite Materials_ Theory, Product Preview

- Handbook of textile design_Principles, processes and practice Preview

- Handbook of nonwovens Preview

- Handbook of Weaving Preview

- Industrial practices in weaving preparatory Preview

- Industrial practices in weaving preparatory Preview

- Innovative jacquard textile design using digital technologies Preview

- Interior Textiles Design and Development Preview

- Knitting Technology Preview

- Mechanisms of flat weaving technology Preview

- Nanofibers and Nanotechnology in textile Preview

- Nonwoven fabrics Preview

- Performance of Home Textiles Preview

- Principles of Fabric Formation Preview

- Reference Book of Textile Technology Knitting Preview

- Reference Book of Textile Technology Nonwovens Preview

- Reference Book of Textile Technology Weaving Preview

- Specialist Yarn and Fabric Structurs-Developments and Applications Preview

- Structure and Mechanics of Woven Fabrics Preview

- Textile Design-Principles, advances and applications Preview

- Textile mechanisms in spinning and weaving machines Preview

- Textile Spinning, Weaving and Desizing Preview

- Visual Texture on Fabric Create Stunning Art Cloth with Water Preview

- Watson’s Advanced Textile Design. Compound Woven Structures Preview

- Watson’s Textile Design and Colour_ Elementary Weaves and Figured Fabrics Preview

- Weaving Preparation Technology Preview

- Weaving_Conversion_of_Yarn to fabric Preview

- Woollen and Worsted Woven Fabric Design Preview

- Woven fabric structure design and product planning Preview

- Woven Terry Fabrics_ Manufacturing and Quality Management Preview

- Woven Textile Structure_ Theory and Applications Preview

- Woven Textile Structure_Theory and Applications Preview

- Woven textiles_ Principles, technologies and applications Preview

- Wowen fabric Engineering Preview

Books on Wet Processing / Dyeing / Finishing / Printing

- Advances in the dyeing and finishing of technical textiles

- Advances in Treating Textile

- Basic Principles of Textile Coloration

- Characterization and Treatment of Textile Wastewater

- Chemical finishing of textiles

- Chemical_Testing_of_Textiles

- Chemistry of the Textiles Industry

- Coated_and_Laminated_Textiles-

- Colour Design Theories and Applications

- Colour measurement Principles, advances,and industrial applications

- Colour_Management_in_Textiles

- Digital_Printing_of_Textiles

- Dyeing and Chemical Technology of Textile Fibres

- Environmental_Aspects_of_Textile_Dyeing

- Experiments in Textile and Fibre Chemistry

- Functional finishes for textiles _ improving comfort, performance and protection

- Fundamentals and Practices in Colouration of Textiles

- Handbook of Detergents__Part D-Formulation

- Handbook of natural dyes and pigments

- Handbook_of_Textile_and_Industrial

- Handbook_of_Textile_and_Industrial

- Ink Jet Textile Printing

- Natural Dyes

- Physico-chemical Aspects of Textile Coloration

- Principles of colour and appearance measurement_ Object appearance, colour perception and instrumental measurement. Volume 1

- Principles of Colour and Appearance Measurement_ Volume 2_ Visual Measurement of Colour, Colour Comparison and Management

- Reference Book of Textile Technology _Finishing

- Simulation and Control of the Dyeing Process-

- Simulation in textile technology_ Theory and applications

- Textile Application of the Color Sensitivity of Dye Mixtures

- Textile dyes

- Textile Fibers, Dyes, Finishes and Process_A Concise Guide

- Textile finishing chemicals an Industrial Guide

- Textile Printing

- Textile Wastewater Treatment

- Textile_dyes

- Textile_Processing with Enzyme

- Textiles and environment

Books on Apparel / Garments Production / Industrial Engineering / Sewing / Merchandizing / Washing / Garments Dyeing

- Advances in apparel production

- Advances in Women’s Intimate Apparel Technology

- Anthropometry, apparel sizing and design

- Apparel Manufacturing Technology

- Carr and Latham’s Technology of Clothing Manufacture

- Clothing Appearance and Fit Science and Technology

- Clothing Biosensory Engineering

- Clothing for Children and Teenagers. Anthropometry, Sizing and Fit

- Computer Technology for Textiles and Apparel

- Denim_ Manufacture, Finishing and Applications

- Design of clothing manufacturing processes_ A systematic approach to planning, scheduling and control

- Designing apparel for consumers _ the impact of body shape and size

- Dress Behind Bars_ Prison Clothing as Criminality

- Engineering apparel fabrics and garments

- Ergonomics in the garment industry

- ERP for Textiles and Apparel Industry

- Garment Manufacturing Technology

- Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing

- Handbook of Sustainable Apparel Production

- How to Use, Adapt, and Design Sewing Patterns

- Improving Comfort in Clothing Engineering

- Industrial cutting of textile materials

- Industrial engineering in apparel production

- Information Systems for the Fashion and Apparel Industry

- Innovation and technology of women’s intimate apparel

- Introduction to nonwovens technology

- Joining Textiles Principles and Applications

- Making Sweatshops_ The Globalization of the U.S. Apparel Industry

- Management of Technology Systems in the Garment Industry

- Metric Pattern Cutting for Menswear

- Metric Pattern Cutting for Women’s Wear

- Pattern cutting for clothing using CAD_ How to use Lectra Modaris pattern cutting software

- Product safety and restricted substance in apparel

- Quality Characterisation of Apparel

- Retail Product Management_Buying and Merchandising

- Science in Clothing Comfort

- Scientific Protocols for Forensic Examination of Clothing

- Sizing in Clothing- Developing Effective Sizing Systems for Ready‐to‐wear Clothing

- Solutions to problems in the textile and garment industry

- Statistics for textiles and apparel management

- Strategic management in garment industry

- Surface_Modification_of_Textiles

- Sustainable Apparel Production_processing and recycling

- The Apparel Industry

- The dirty side of the garment industry _ fast fashion and its negative impact on environment and society

- Virtual Clothing_ Theory and Practice

- Visual Merchandising_ Windows and in-store displays for retail

- Zara and her Sisters_The Story of the World’s Largest Clothing Retailer

Books on Fashion Design / Visual Merchandizing / Product Development

- Basics Fashion Design 02 Textiles and Fashion

- Career in Textile and Fashion Designing

- Clothing & Fashion

- Clothing_Fashion,Fabrics and Construction

- Fashion Designing and Sewing Technology

- Fashion Merchandising

- Fashion Retail Supply Chain Management_ A Systems Optimization Approach

- Fashion Supply Chain Management

- Fashion Supply Chain Management Using Radio Frequency Identification (RFID) Technologies-

- Figure Drawing for Fashion Design

- Information Systems for the Fashion and Apparel Industry-

- Patternmaking for Fashion Design

- Sewing for Fashion Designers

Books on Textile Management / Quality Control

- Effective Implementation of Quality Management Systems

- Humidification and Ventilation Management in Textile Industry

- Lean Six Sigma for Engineers and Managers_ With Applied Case Studies

- Management of Technology Systems in the Garment Industry

- Quality Characterisation of Apparel

- Solutions to problems in the textile and garment industry

- Strategic management in garment industry

- Textile Processes_ Quality Control and Design of Experiments

- The Fundamentals of Production Planning and Control

- The fundamentals of quality assurance in the textile industry

- Work quality management in the textile industry

All in One

- 3-D Fibrous Assemblies_ Properties, Applications and Modelling of Three-Dimensional Textile Structures

- A Novel Green Treatment for Textiles_ Plasma Treatment as a Sustainable Technology

- Coated Textiles_Principles and Applications

- Denim_ Manufacture, Finishing and Applications-

- Dictionary of Textile Finishing. Deutsch_englisch, English_german

- Engineering Textiles-Integrating the design and manufacture of textile products

- Environmental Impact of Textiles. Production, Processes and Protection

- Handbook of Sustainable Textile Production

- Handbook of Worsted Wool and Blended Suiting Process

- Know all about clothing Technology

- Mechanics and calculations of textile machinery

- Modern Textile Technology

- Process control in textile manufacturing

- Surface Characteristics of Fibers and Textiles

- Sustainable Textiles_ Life Cycle and Environmental Impact

- Textile Engineering

- Textile Mathematics_Part I

- Textile Sizing-

- Textile_Mathematics_Part II

- Textiles for Industrial Applications

- Textiles_ Types, Uses and Production Methods

- Textiles_and_Fashion

- The World Trade Organization and International Denim Trading

- The_China_and_Hong_Kong denim industry

- Training and Development of Technical Staff in the Textile Industry

- Training_and_development of technical staff in textile industry-

- Tufted Carpet_Textile Fibers, Dyes, Finishes and Processes

Advanced Textile Books

- Advanced fibrous composite materials for ballistic protection

- Absorbent_Technology

- Activated Carbon Fiber and Textiles

- Adaptive AND FUNCTIONAL POLYMERS, TEXTILES AND THEIR

- Advanced fibrous composite materials for ballistic protection

- Advanced Textiles for Wound Care

- Advances in 3D textiles

- Advances in Carpet Manufacture

- Advances in Fire Retardant Materials

- Advances in military textiles and personal equipment

- Advances in Polymer Coated Textiles

- Advances in shape memory polymers

- Advances in smart medical textiles

- Advances in Textile Biotechnology-

- Advances in textile engineering

- Analytical Electrochemistry in Textiles

- Antimicrobial Textiles

- Apparel machinery and equipments

- Biofunctional Textiles and the Skin

- Biologically Inspired Textiles

- Biomechanical Engineering of Textiles and Clothing

- Biomedical Textiles for Orthopaedic and Surgical Applications

- Bioprocessing of Textiles

- Biotextiles as medical implants

- Chemical Protective Clothing

- Design and Manufacture of Textile Composites

- Development of Nanotechnology in Textiles

- Ecotextiles_

- Electronic Textiles_ Smart Fabrics and Wearable Technology

- Electronics and Computing in Textiles

- Electronics in textiles and clothing _ design, products and applications

- Electrospinning of Nanofibers in Textiles

- Electrospun Nanofibers

- Engineering textiles _ research methodologies, concepts, and modern applications

- Fibrous and composite materials for civil engineering applications

- Functional nanofibers and their applications

- Functional Textiles for Improved Performance, Protection and Health

- Geotextiles_ From Design to Applications

- Global Denim

- Handbook of fire resistant textiles

- Handbook of Medical Textiles

- Handbook of Technical Textiles, Volume 1 _ Technical Textile Processes

- Handbook of Technical Textiles, Volume 2_Technical Textile Applications

- Handbook of Tensile Properties of Textile and Technical Fibres

- High performance textiles and their applications-

- Materials and technology for sportswear and performance apparel

- Materials in Sports Equipment- Volume 1

- Materials in Sports Equipment Volume 2

- Medical and heaithcare textiles-

- Medical Textile Materials

- Medical textiles and biomaterials for healthcare

- Medical_Textiles

- Military_Textiles

- Modelling and Predicting Textile Behaviour

- Modern textile characterization methods

- Multidisciplinary know-how for smart textiles developers

- Multiscale materials modelling

- Nanostructured polymer blends and composites in textiles

- New millennium fibers

- New Product Development in Textiles_ Innovation and Production

- Novel Fire Retardant Polymers and Composite Materials

- Smart bandage technologies_ design and application

- Smart Clothing_Technology and Applications

- Smart Textiles and their Applications

- Smart Textiles for Designers_ Inventing the Future of Fabrics

- Smart textiles for protection-

- Smart_Clothes_and_Wearable-

- Smart_Fibres,_Fabrics_and_Clothing

- Smart_Textile_Coatings_and_Laminates

- Smart_Textiles_for_Medicine_an healthcare

- Soft Computing in Textile Engineering

- Structure and Properties of High-Performance Fibers

- Textile advances in the automotive industry

- Textile-led Design for the Active Ageing Population

- Textiles and human thermophysiological comfort in the indoor environment

- Textiles for Sportswear-

- Textiles in automotive engineering-

- Textiles, polymers and composites for buildings

- Textiles_for_Cold_Weather_Apparel

- Textiles_for_Hygiene_and_Infection control

- Textiles_for_Protection

- Textiles_in_Sport

- The global textile and clothing industry_ Technological advances and future challenges

- Theory of Structure and Mechanics of Fibrous Assemblies

- Thermal Protective Clothing for Firefighters

- Thermal_and_moisture_transport

- Understanding and improving the durability of textiles

- Update on Flame Retardant Textiles _ State of the Art, Environmental Issues and Innovative Solutions

- Wearable_electronics_and_photonics

- Woven Composites

Others Book

- Assessing the environmental impact of textiles and the clothing supply chain

- Buildings, Clothing and Art

- ERP_ Tools, Techniques, and Applications for Integrating the Supply Chain

- Fundamentals of designing for textiles and other end uses

- Optimizing decision making in the apparel supply chain using artificial intelligence (AI)_ From production to retail

- Product Design and Factory Development (The Handbook of Manufacturing Engineering, Second Edition) (Volume 1)

- Structure and Mechanics of Textile Fibre Assemblies

- Structure_and_Mechanics_of_Textile_fibre assemblies

TEXTILE BOOKS FREE DONWLOAD

DC Tachometer Generator

DC Tachometer Generator

The DC tachometer generator is a speed measuring device. These are used in Machine tools handling & lifting systems, Paper Manufacturing machines , Textile machines, Glass production lines, Rolling mills, railway industry etc.

The word “Tachometer” is derived from the greek word “Tacho” , which means “speed”. Tachometers are of two types, these are : electrical tachometers & mechanical tachometers.

Electrical tachometers are also known as Tachometer generators. Tachometer generator (or, tachogenerator) is a device that is used for measuring the speed of a shaft or rotating body & converting into a voltage so that it can be measured.

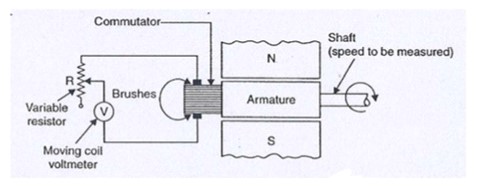

Construction :

In its construction, it has

- a permanent magnet,

- armature,

- commutator,

- brushes,

- variable resistor

- a moving coil voltmeter

Schematic Diagram :

Figure 1: Schematic diagram of DC Tachogenerator

The armature of the dc tachometer is kept between a permanent magnetic field. The armature is coupled with the machine whose speed is to be measured.

Now, as the shaft of the machine revolves, the armature of the tachometer revolves with it, in the magnetic field, which produces an EMF.

The commutator collects generated current (i.e. EMF) from the armature & converts the AC EMF to DC EMF. The brushes collect current from the commutator & supplies it to the exernal circuitry of the tachometer (i.e voltmeter & resistor). The EMF induced is measured using a moving coil voltmeter. The moving coil voltmeter has an uniform scale, callibrated in speed directly. So, speed of macine can be measured.

The EMF generated is proportional to the number of the flux & the speed of the revolving armarture (i.e. the speed of the revolving machine). Now, as the electric field of the permanent magnet is fixed, the EMF generated in this case, is directly proportinal to the speed of the machine.

The variable resistor, connected in series, is used to limit the output current flow to short circuit condition. The polarity of the output voltage indicates the direction of rotation, which is a major advantage of using a DC tachometer generator.

Disadvantages of using a DC tachometer generator are that the commutator & brushes require periodic maintenance & the output is nonlinear.

However, there has been a lot of modifications & advancements in the technology of modern day DC tachometer generators. It is also evident that with the advent of various modern speed measuring technologies, the use of DC tachometer generators has decreased.

DC Tachometer Generator

Knitting | Knitting Types | Advantages and Disadvantages of Knitting | Properties of Knitting

Knitting

Knitting is the second most popular technique of fabric or garment formation by inter-looping one or one set of yarns. Continuous length of yarn is converted into vertically intermeshed loops either by hand or by machine. The most important parameter of a knitted fabric is loop length which can be varied during knitting by changing machine parameters, process parameters and yarn parameters. The other important parameters of a knitted fabric which are considered for assessing the quality of the fabric are courses per inch, wales per inch, stitch density, GSM and tightness factor.

Types of knitting:

- Weft knitting

- Warp knitting

Weft knitting is where the loops are formed one after another in a weft-ways direction as the fabric is formed. Warp knitting is where a set of warp yarns are simultaneously formed into loops.

Difference between warp and weft knits:

[table id=20 /]

Types of weft knitting machines:

Flat knitting

Types of weft knitted structures:

- Single jersey structure

- Double jersey structure

- Double jersey structure:

- Rib structure

- Purl structure

- Interlock structure

Needles used in knitting:

- Bearded needle

- Latch needle

- Compound needle

Yarn preparation for knitting fabric

Knitting process will need cone, not cheese.

- Because the yarn tension maintain in the knitting will be constant. If using the cheese during the unwinding yarn will be rubbed on cheese surface.so that tension will be vary because of low twist yarn is suitable for knitting.

- Instead of using the cone unwinding will be very easy.

- During cone winding, the waxy roller will be essential because the yarn will be contacted with the knitting needles. Either the yarn will damage or the needle will be damaged.

- The cone winding machine will be run at slow speed due to the tension variation yarn will not be uniform.

- If using high speed winding machine cotton combed yarn will be better.

- Electronic yarn clearer will be used.

- Separate drive for drum and the package.

- Pneumatic splicing must be needed.

- Additive type of tensioner needed, whatever the variation in input tension output tension will be compensated by amontons law principle.

- Unwinding accelerator or the balloon breaker needed for maintaining the same tension.

Properties required for knitting:

- Flexural rigidity: Low flexural rigidity yarn can bend easily

- Torsional rigidity: When yarns are looped they are subjected to torsion yarns have low torsional rigidity will work better in knitting.

Knitting fabric properties:

[table id=18 /]

Other essential properties: woven vs knits

[table id=19 /]

Due to the high permeability,

- Air can be allowed into the fabric.

- Very useful in summer.

If knits are permeable, why it is preferred in sweaters for winter garments?

Because the thickness of the fabric will be more, so that more air will be drape inside the fabric. Air is a poor conductor (thermal insulator), so that air will be heated near to body. So, our body will be warm.

Advantages of knitting:

- Fabric can be produced from minimum number of yarns, even only one yarn.

- The extensibility and stability of the fabric can be engineered.

- The desirable compactness of the fabric can be achieved easily.

- Loop structures are easily distorted under tension in application, which imparts more freedom of movement and comfort the wearer.

- Wastage of yarn during conversion of yarn into fabric by knitting is negligible.

- Knitting can produce fabrics which are very much suitable for intimate wears as well as for technical application.

- Shaping can be done at the time of knitting on the resultant fabric.

- The number of yarns to be knitted in the same fabric can be varied by selection.

- Design possibilities will be much higher.

Disadvantages in knitting:

- Dimensional stability will be lower than the woven fabric.

- Glass fabric is very critical to knitting because bending rigidity will be higher. But in the weaving we can produce glass fabric easily.

- Count range will be low in the knitting machine, but weaving is the versatile machine to produce any count of fabrics.

Reason for growth of knitting industry:

Productivity of looms at particular time

[table id=17 /]

Machine productivity higher.

Labour less organised.

Floor space: Compared to auto loom for the same production

Warp knitting 1/10 th

Weft knitting 1/8 th

Power consumption: Compared to auto loom for the same production 1/4 th to 1/5 th will be required.

Yarn and yarn preparation :

- Low TPI yarns will be needed for knitting. So that spinning production will be higher.

- There is no need for warping, sizing and drawing-in processes.

- Only warp knitting need warping process.

Time required for getting an order executed is less than weaving.

Modern knitting machines particularly warp knitting machines can produce various type of technical textiles ( medical textiles, automobile textiles, geotextiles, etc.)

Computer aided designing and manufacturing in knitting have made it possible to manufacture any desired structure within a short time at reasonable price.

Knitting | Knitting Types | Advantages and Disadvantages of Knitting | Properties of Knitting

Knitting | Knitting Types | Advantages and Disadvantages of Knitting | Properties of Knitting