Melt Spinning, Dry spinning and Wet Spinning Method :

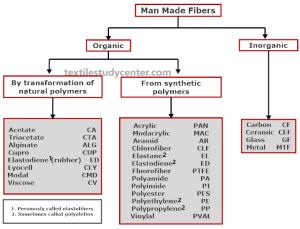

Man-made fibers are manufactured by spinning the polymer. There are three major types of spinning process. They are-

Melt Spinning:

Melt spinning uses heat to melt the polymer to a viscosity suitable for extrusion. This type of spinning is used for polymers that are not decomposed or degraded by the temperatures necessary for extrusion. This method is used by 70% of the fibers.

Spinning process:

❶ In melt spinning, polymer is heated and it melts to form a liquid spinning solution or dope.

❷ Chips of polymers are fed to a hopper which is heated. There is a grid (sieve) at the base which permits only molten liquid to pass through.

❸ Then the solution is purified by filter.

❹ The molten polymer is extruded at high pressure and constant rate through a spinneret into a relatively cooler air stream that solidifies the filaments.

❺ Finally the filament yarn either is immediately wound onto bobbins or is further treated for certain desired characteristics or end use.

Example: Melt spinning is used for the production of polyester, nylon, olefin, saran and glass fibers.

Advantages:

►High speed (275 to 1500 yds/min); (4000 yds/min spin draw)

►No solvents

►No purification problems

Disadvantages:

►Separate drawing step (unless spin draw)

Dry spinning:

Dry spinning is used for polymers that need to be dissolved in a solvent. Solvent spinning (dry spinning and wet spinning) are used by 30% of the fibers.

Spinning process:

❶ In dry spinning, a volatile solvent is used to dissolve the raw materials and form a salutation.

❷ Then the solution is purified by filter.

❸ The solution is extruded through a spinneret into a warm air chamber where the solvent evaporates, solidifying the fine filaments.

❹ Finally the filament yarn either is immediately wound onto bobbins or is further treated for certain desired characteristics or end use.

Example: Dry spinning is used in the production of acetate, triacetate, and some acrylic, modacrylic, spandex, and vinyon (PVC,PVA) fibers.

Advantages:

►Yarn does not require purification

Disadvantages:

►Flammable solvent hazards

►Solvent recovery

►Slow (200-400 yds/min)

Wet Spinning:

This is the oldest, most complex and also the most expensive method of man-made yarn manufacture. This type of spinning is applied to polymers which do not melt and dissolve only in non-volatile or thermal unstable solvents.

Vedio: Wet spinning

Spinning process:

❶ In wet spinning, a non-volatile solvent is used to convert the raw material into a solution.

❷ The solvent is extruded through the spinneret either by simply washing it out or by a chemical reaction between the polymer solution and a reagent in the spinning bath.

❸ After extrusion, the solvent is removed in a liquid coagulation medium.

❹ Finally the filament yarn either is immediately wound onto bobbins or is further treated for certain desired characteristics or end use.

Example: Wet spinning is used in the production of aramid, Lyocell, PVC, Vinyon (PVA), viscose rayon, spandex, acrylic and modacrylic fibers.

Advantages:

►Large tows can be handled

Disadvantages:

►Slow (70-150 yds/min)

►Washing to remove impurities

►Solvent and chemical recovery

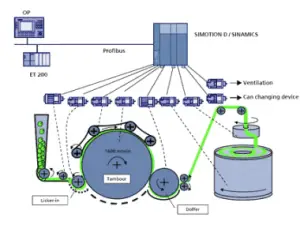

General process diagram of melt, dry and wet spinning process

Difference between Melt spinning, Dry spinning & Wet spinning

Melt Spinning , Dry spinning and Wet Spinning Method